Applications

The Visual Factory in Action

- The CL50 Pro Column Light with Audible uses bright visual signals and sound alerts to indicate workstation status. Operators are immediately notified of task completion or process errors for quicker response.

- The SD50 Pro Status Display shows clear, text-based equipment status messages visible up to 10 meters away. This improves operator awareness and speeds up decision-making on the production floor.

- The WLF12 Pro Flexible Strip Light provides real-time visual feedback on the pallet shrink wrapping process. Its segmented illumination allows operators to easily monitor progress without manual checks.

- The Illuminated E-stop makes it easy to locate issues along a conveyor with bright, visible lighting. Faster identification allows for quicker responses, reducing downtime and improving safety

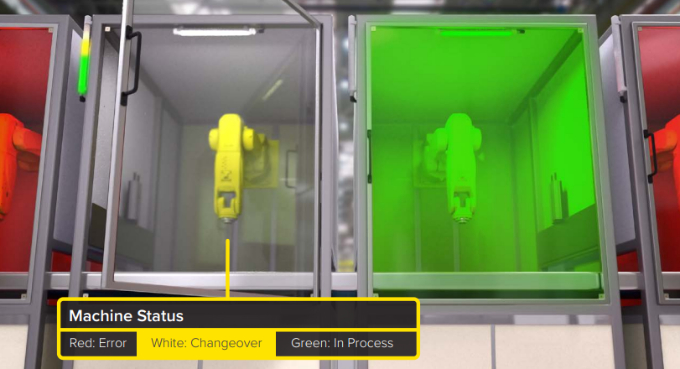

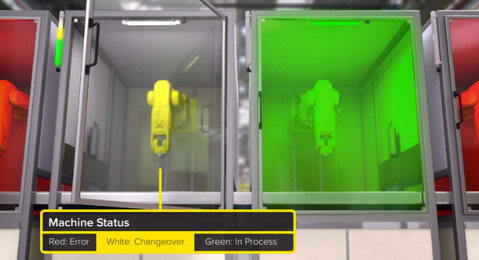

Product Changeover on Assembly Lines

Challenge

At the end of a line, pallet wrapping machines need to operate consistently and reliably because any backup can have a ripple effect that extends throughout the End-of-arm tools must be changed to accommodate product changeover. Making sure this process is efficient keeps production smooth and overhead costs down. Knowing at a glance which stations are ready for changeover lets maintenance staff and/or operators respond quickly when changes are needed, even from a considerable distance away.

Solution

A WLS27 Strip Light mounted in the work cell fills the area with green light to indicate the machine is in-process. When the machine completes its task and needs a different tool, the light changes to red, clearly indicating it is ready for attention. As an operator opens the cell door, the WLS27 switches to bright white illumination, making it easier for the operator to see and perform the changeover efficiently.

Status Indication on a Pallet Wrapper

Challenge

At the end of a line, pallet wrapping machines need to operate consistently and reliably because any backup can have a ripple effect that extends throughout the production line. Equipment status must be quickly and clearly communicated to operators, even if they are a distance away, so they can replace shrink wrap rolls, adjust wrap tension and alignment, and ensure wrapped pallets move out in a timely manner.

Solution

Using standard M12 connections and high strength adhesive backing for bracketless mounting, WLF12 Pro Flexible Light Strips easily integrate into pallet wrapper designs without adding bulk to already sizeable machines. Nineteen colors, plus multiple animations, can be easily programmed to convey sensor information on all sides of the equipment, including machine status around the top and process status visualization on the sides.

Application Examples

- Integrated indications on machines

- Indication on mobile equipment

- Indication for pick light systems and kitting stations

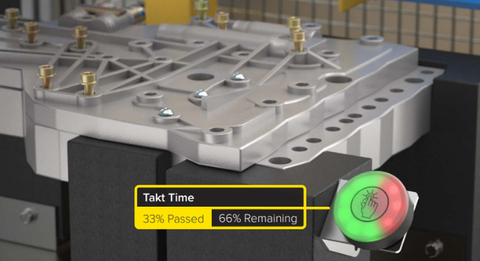

Maintaining Assembly Line Takt Time with Minimal Disruption

Challenge

Maintaining takt time is critical to production lines relying on consistent and efficient manual assembly processes. Any slowdowns can create a domino effect that can lead to missed production goals and increased operational costs. Workers need to be aware of their pace so they can self-correct without disrupting production.

Solution

The K50 Pro Touch Button with IO-Link ensures optimal takt time management by providing real-time, customizable feedback with multicolor LEDs and animations. Its sequential timer mode signals workers to stay on pace, while IO-Link technology allows remote configuration and productivity monitoring.

- Technologies

- Asset Monitoring Gateway with Cloud ID

- Asset Monitoring Gateway with SNAP ID

- Codesys

- Condition Monitoring

- Ethernet in Hazardous Locations

- Field Logic Controller

- Industrial Cloud

- Industry 4.0

- IO-Link

- Machine Safety

- Modular Machines

- Module Type Package

- Multiprotocol Ethernet

- Pick-to-Light

- Profinet

- RFID

- Snap Signal

- Sustainability

- The Visual Factory