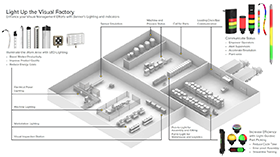

The Visual Factory

Give Your Equipment A Voice With Lighting And Indication Products

The visual factory comprises three key applications for lighting and indication in industrial settings. These applications include the ability to help machines and workstations quickly communicate their status to people nearby, use light to guide workers to perform certain tasks such as part picking, and to provide illumination for work areas and tasks. The lighting products used in the visual factory include tower lights, strip lights, touch buttons, and indicators. The capabilities of products in the visual factory range from simple single-color lights and indicators to lights that offer advanced multicolor animations and multi-tone audible alarms.

Product Innovation for the Visual Factory

Banner leads the advancement of the visual factory with its broad and ever-expanding portfolio of industrial LED task lights, tower lights, indicators, and touch buttons that are engineered to provide bright, superior-quality illumination, clear status indication, and unmistakable operator guidance. These products offer the advantages of low power, long life, and maintenance-free operation inherent in LED technology built into rugged, industrial-grade packages.

Banner’s programmable lights can communicate more about the status of machines because they allow you to easily configure color, flashing, dimming, and advanced animations such as rotation, strobing, two-color display, two-color rotation, two-color flashing, and chase. Controlling these colors and animations can be achieved in several ways. First, colors and animations may be configured using Banner’s free Pro Editor software and then controlled through simple discrete I/O. Models with IO-Link® require no special configuration and are simply controlled by commands from the IO-Link master. For pick-to-light, put-to-light, or other operator guidance applications, PICK-IQ® (based on Modbus®) provides a method to create simple connections between devices to reduce wiring and installation time, along with simplifying the programming and setup of the system.

Programmable lights offer the additional benefit of helping companies reduce inventory SKUs by consolidating several lights into one programmable unit. For example, consider a machine builder who stocks a variety of three-segment tower lights, each with a different combination of colors and flash patterns. With Banner’s programmable tower lights, the machine builder could standardize on one tower light model and simply load the lighting configuration needed for the application during the machine build. This inventory consolidation benefit carries through to Banner’s touch buttons and programmable strip lights as well.

- Technologies

- Asset Monitoring Gateway with Cloud ID

- Asset Monitoring Gateway with SNAP ID

- Codesys

- Condition Monitoring

- Ethernet in Hazardous Locations

- Field Logic Controller

- Industrial Cloud

- Industry 4.0

- IO-Link

- Machine Safety

- Modular Machines

- Module Type Package

- Multiprotocol Ethernet

- Pick-to-Light

- Profinet

- RFID

- Snap Signal

- Sustainability

- The Visual Factory